HELIOS Hybrid Battery Concept: thinking out-of-the-cell!

New research by the HELIOS team published in the Journal of Energy Storage puts forward a new scalable hybrid battery concept. Find out how two battery chemistries can be mixed at pack level achieving milestones in fast charging and lifetime.

By Dr. Farshid Naseri (Aarhus University, Denmark).

Many believe that the heart of an electric car is its lithium-ion battery pack. It’s the battery that determines how far the EV can drive or how fast the EV can be refueled. Battery cells have limited power and energy and the battery pack must contain hundreds to thousands of lithium-ion cells to scale to the voltage, energy, and power levels required by an electric car. The cell specification is critical to achieving a competitive battery pack design. An ideal battery should be as small as possible, carry a significant amount of energy, charge as fast as possible, and last for a long time. However, these requirements conflict with each other and there is usually an engineering challenge to meet a good trade-off.

Since almost a decade ago, battery companies and automakers are racing to improve battery cell technology, to enable building packs that have higher energy and power density. The energy density determines how much energy the battery can contain with respect to its weight while power density determines how fast the stored energy can be released. Both factors are important to achieve high performance in terms of driving range, acceleration, charging speed, and longevity of the overall pack and EV. Despite the advancements, we may be close to what lithium-ion cells can achieve, and without a game-changing pack design, it's hard to reach a significant breakthrough. Small incremental improvements are hard to scale, which challenges the economy of manufacturing.

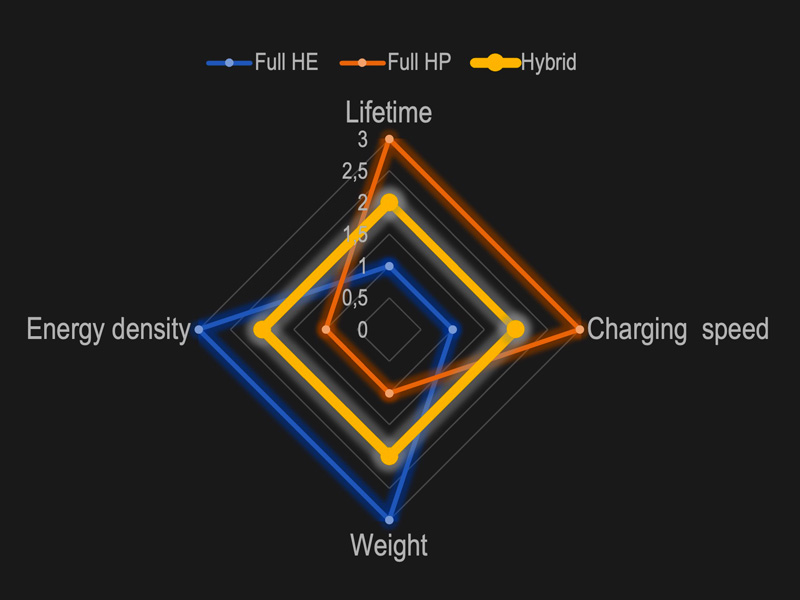

On an important note, there is usually a cell design trade-off between energy and power requirements. Different lithium-ion cells with different chemistries are commercially available nowadays. Nevertheless, these cells are optimized to either achieve a high energy density such as those using Nickel Manganese Cobalt (NMC) Oxide cathodes or high power density such as cells with Lithium Titanite Oxide (LTO) anode. High-Energy (HE) batteries are produced with thick electrodes to store a large amount of active material, which consequently increases the energy content and the driving range. In contrast, High-Power (HP) cells use thin electrodes to reduce the internal resistance thereby improving the power capability and acceleration. It is challenging to simultaneously achieve high energy and power densities within a single battery cell as it will result in bulky cells.

Both energy and power are important to build a high-performant battery pack. The existing battery packs are designed based on mono cell type using either high-energy or high-power cells, which is limiting. Firstly, the battery pack might need to be over-designed in terms of energy (when using HE cells) or power (when using HP cells) to meet the concurrent energy and power requirements for some use cases and driving conditions, which will result in non-optimal design and battery pack over-sizing causing additional weight, volume, and cost. Secondly, designs with mono cells are hard to scale to meet the requirements of different use cases when different power-to-energy ratios might be needed, e.g. in the case of a small car to an electric truck. We need to think out-of-the-cell to overcome these challenges!

But what if we could hybridize two cells in one pack? Our recent open-access publication in the Journal of Energy Storage (https://www.sciencedirect.com/science/article/pii/S2352152X2201756X) presents a disruptive solution that can transform how the battery packs are designed. The article proposes a new type of battery module that combines NMC cells with LTO cells. Inside each module, there exists a power electronics converter to interface the two cells and operate them. The number of cells in the modules is optimized to precisely match the power and energy requirements of target driving cycles without any overdesign. The proposed design decouples energy and power which has also shown to better meet the requirements for scalability due to the flexibility of adjusting the energy-to-power ratio at the pack level. In other words, the cell number and arrangement in the hybrid battery can be easily changed to adjust the energy and power requirements of the pack for different use cases. Thus, the proposed hybrid battery solution will help to better meet the diverse set of consumer needs.

Figure 1: Spider plot depicting the design trade-off attainable with the hybrid battery compared to the pack composed of only HE or HP cells

And how does the hybrid battery work? The brain of the hybrid pack is an intelligent energy management strategy that decides how the load should be split between the NMC and LTO cells at different driving conditions such as during cruising on a highway, acceleration, or braking. The energy management is based on an online optimization running on a digital twin (read about digital twin in HELIOS here) which tries to maximize the lifetime of the overall pack and minimizes the consumption of energy to increase the driving range.

The battery concept was tested on a Mitsubishi i-MiEV model and according to the report, it can be charged up to 70% in only 6 minutes, which is achieved through the use of LTO cells, which can be fast charged, perfectly. In addition to that, the driving warrantee was shown to be improved by more than 40,000 km compared to the battery pack design only with NMC cells. The longer driving achievable is also attributed to the robust LTO cells which act as “shock-absorber” drifting the transients from NMC cells which tend to degrade very fast under high discharge rates.

The hybrid battery concept is being developed under the framework of the EU-funded HELIOS project which is being coordinated by the ECE Department, at Aarhus University. Through various work packages and tasks, eighteen partners including universities, research institutions, and SMEs from 8 different countries across Europe are developing various hardware and software systems and subsystems that will drive this hybrid battery solution. The concept is planned to be prototyped next year by integrating it into a small-size car in Denmark and an electric bus in Turkey. Stay tuned if interested to learn how the art of pack design will turn out.

More information about the hybrid pack design can be found in the article freely available at: https://www.sciencedirect.com/science/article/pii/S2352152X2201756X